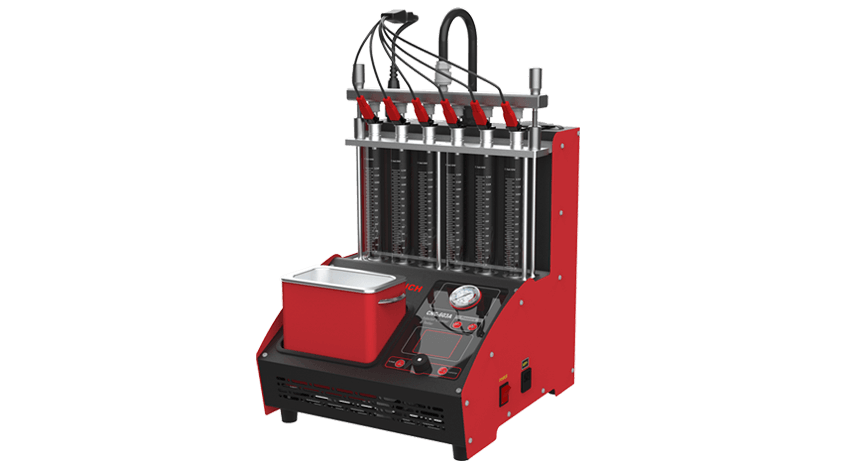

CNC605 launched by SmartSafe, is a Injector Cleaner and Tester suitable for GDI, EFI, SFI and other injectors. The injector can be cleaned and tested by simulating the engine condition. It can also be used to clean the fuel injector ad fuel supply system on the vehicle without disassembly. It is ideal for repair and maintenance service centers!

contact

For a more comprehensive introduction to SmartSafe CNC605 injector cleaning machine, we will provide you with wonderful video explanations to learn more about the operation of the product, click training center.

Suitable for different occasions and functions, CNC605 Injector Cleaner and Tester is a classic device for SmartSafe cleaning and maintenance.

|

Functions |

Description |

√ |

|

Working Mode Selection

|

Can select GDI or EFI working mode based on the injector type

|

√ |

|

Ultrasonic Cleaning

|

Capable of simultaneously ultrasonic cleaning multiple injectors, effectively removing carbon buildup

|

√ |

|

Uniformity/Spray Testing

|

Detects the uniformity of fuel injection quantity for each injector and allows comprehensive

observation of the injector spray pattern using background lighting

|

√ |

|

Sealing Test

|

Tests the sealing and leakage of injectors under system pressure

|

√ |

|

Fuel Injection Quantity Detection

|

Measures the fuel injection quantity of injectors under a constant 15-second injection condition |

√ |

|

Automatic Cleaning and Testing

|

Under specific working parameters, realistically simulates injector testing under various conditions

|

√ |

|

Reverse Flush

|

For the uniformity/spray testing item, performs a reverse flush using a reverse flush adapter to remove

internal injector contaminants and residues attached to the filter screen

|

√ |

|

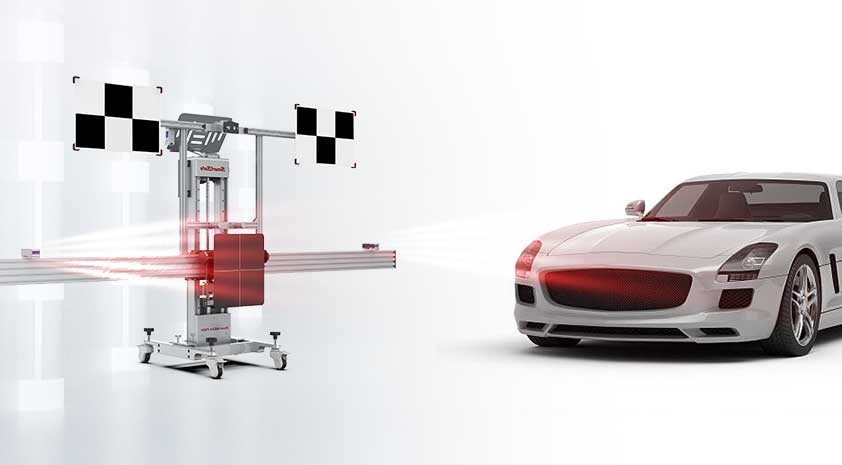

Non-Dismantle Cleaning

|

Equipped with various non-dismantle cleaning adapters, allowing non-dismantle cleaning

and maintenance for multiple vehicle models

|

√ |

|

Power Supply

|

AC110V/AC220V 50Hz/60Hz

|

Revolutions Per Minute

|

100~9900rpm Step length 100rpm

|

|

Main Engine Power

|

350W

|

Pulse Width

|

0.5~25ms Step length 0.1ms

|

|

Ultrasonic Cleaning Power

|

100W

|

Timer Range

|

1~30min

|

|

Fuel Pressure

|

0.1~10 bar

|

Tank Capacity

|

3L

|

|

Air Inlet Pressure

|

5~8 bar

|

Size

|

442×490×533mm

|

Do not place anything on the control panel to prevent from breaking the measuring cup because it is made from vulnerable. Do not disconnect hose before the system pressure reaches "0".

Always ensure that the provided power supply is well contacted with ground safely.

The unit is designed with warning function. When the level switch checks the liquid inside the tank less than the lowest line, the unit will utter the warning sound and meanwhile stop the fuel pump and injectors automatically, and then the unit returns to the stop state. The unit will stop warning until the liquid is supplied enough. At this time pressing the ENTER key will run the unit again.

Clean the control panel in time and Keep the pulse signal cable away from the liquid.