contact

|

Functions |

Description |

√ |

|

ADAS automatic centering and paralleling |

Simply push the main frame to the approximate position to activate the automatic centering and paralleling function, meeting the automatic centering and paralleling standards of different vehicles. |

√ |

|

Automatic target lift |

Based on the target's centering and parallel height requirements, the target is automatically raised to the desired calibration position. |

√ |

|

Target finding and tracking |

The beam will automatically rise and fall according to the changes in vehicle height to track the target and ensure that the target is within the camera's field of view. |

√ |

|

Four-wheel alignment measurement |

Supports standard measurement and quick measurement and can measure key parameters such as toe, camber, caster, kingpin inclination, and thrust angle. Supports additional measurements such as wheelbase, wheel track, axle offset, wheel offset, diagonal, center offset, etc. |

√ |

|

Vehicle type database |

Covers the four-wheel alignment data of more than 50000 models worldwide and supports user customization.

|

√ |

|

Terminal wireless connection |

Measurement data is transmitted wirelessly and the four-wheel alignment process is displayed when paired with the ST13 intelligent connection terminal. |

√ |

|

Test report |

Generate ADAS calibration and four-wheel alignment reports, support pre-calibration and post-calibration data comparison, and support report sharing. |

√ |

|

Rated power |

260W |

Main frame left and right motion range |

±90mm |

|

Power supply |

100~264V,50/60Hz |

Main frame rotation range |

士3° |

|

Recommended working distance(wheel alignment) |

1.8~2.2m |

Hub diameter (four-point hub clamp)

|

275~640mm |

|

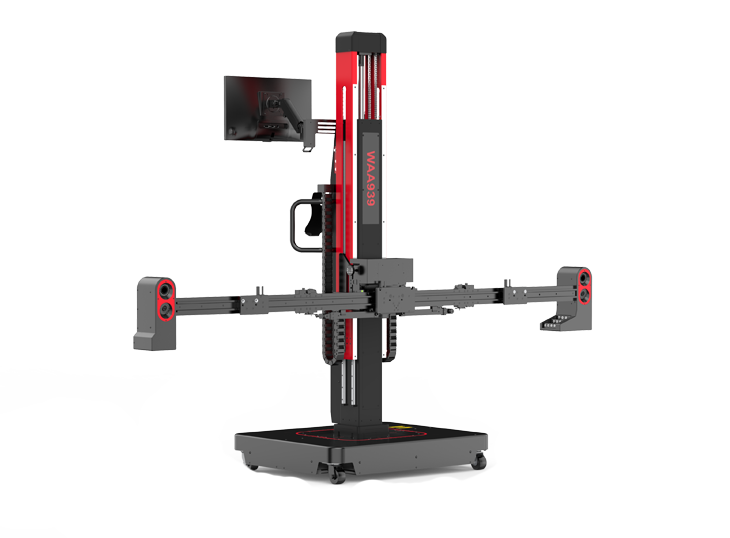

Main frame folded dimensions (length×width×height) |

1500x900x1920mm |

Tire diameter(three-point tire clamp) |

470~1100mm |

|

Beam expanded/folded dimensions |

2780/1500mm |

Operating temperature |

-10~50°C |

|

Main frame height range |

335~2175mm |

Storage temperature |

-20~60°C |

|

Main frame front and rear motion range |

士120mm |

|

|

Be careful when operating each accessory of the ADAS calibration tool.

Use acid- and resin-free grease or oil to wipe the movable components regularly.

Clean the ADAS calibration tool regularly with a mild detergent.

If you use a standard household cleaner, spray it on a damp towel.

If any component is damaged, please use the original replacement component to replace it immediately.