EB480 is an electric vehicle battery pack cell balancer launched by SmartSafe. It is used to quickly solve the problem of inconsistent voltage of lithium battery packs. It is an intelligent and efficient battery pack balancing device.

EB480 can be used for battery testing in various departments such as battery manufacturer after-sales/warehousing, TVC testing, QA quality control, etc., as well as battery maintenance at OEMs and after-sales maintenance at 4S stores. It is suitable for lithium iron phosphate, ternary lithium, lithium titanate, manganese Lithium acid multi-type ev battery packs.

The independent single cell balancing solution supports precise balancing of single cells; supports up to 4 groups of module balancing, with each group up to 12 strings of cell balancing.

Supports ternary lithium, lithium iron phosphate, lithium manganate, and lithium titanate; It supports balanced maintenance parameter setting, selects the preset voltage range according to the battery type, and automatically switches the charge and discharge mode, effectively solving the battery inconsistency problem.

Supports high-precision collection of single-cell voltage parameters, effectively improving overall vehicle power and ensuring battery pack performance.

Supports input overcurrent protection, output overcurrent protection, overvoltage protection, and overtemperature protection.

Supports differentiated comparison between "before equilibrium" and "after equilibrium", and can export equilibrium data; It supports the real-time monitoring of the voltage parameters and equilibrium status of each single cell during the balancing process, making the process clear and visual.

|

Power Input |

AC90~264V/40~60Hz |

Wireless Communication |

WiFi and BT(external WiFi antenna) |

|

Power |

1200W Max |

Equalize Number of Channels |

4X12Pin |

|

Charge and Discharge Voltage Range |

1.8~4.5V |

Equalize Interface |

26Pins X2 |

|

Voltage Detection Accuracy |

土0.1% FS+2mV (maximum range 5V) |

Battery Interface |

24Pin |

|

Charge and Discharge Current Range |

0.1~5A Max |

Display |

7-inch TFT LCD screen, resolution 1024X600 |

|

Current Detection Accuracy |

土1% FS+0.05A (maximum range 5A) |

Communication Interface |

SMA,USB-Device |

|

Battery Temperature Detection Accuracy |

士2°C(-25C~ 85°C) |

Charge Control |

Constant current charging+constant voltage charging |

|

Discharge Mode |

Constant current discharging |

Protection Function |

Input over-current protection, over-voltage protection, output over-current protection, over-temperature protection |

Cell balancing: When the cell voltages in the battery pack are inconsistent, EB480 can be used to balance the cells to achieve consistent cell voltages within the battery pack.

Trim after replacing battery core: After the maintenance personnel replace the battery cells in the module, they can use EB480 to equalize the battery cells in the module to achieve consistent battery voltage.

When the battery life of an electric vehicle is reduced, there is empty power, the charging is not saturated, etc., battery balancing can be used to reduce the difference between each battery cell to achieve the effect of increasing battery life.

Principle of wooden barrel charging and discharging of power batteries: As the service life of electric vehicles increases, the gap between single battery cells will gradually be enlarged. Industrial manufacturing cannot guarantee that each battery is 100% the same, just like there are no two identical leaves on the same tree.

Even if the two single cells are exactly the same, but their positions in the battery module are different, the ambient temperature of cell 1 may be higher than that of cell 2, and the single cell will also have some problems after multiple charges and discharges. The difference will gradually increase with the service life.

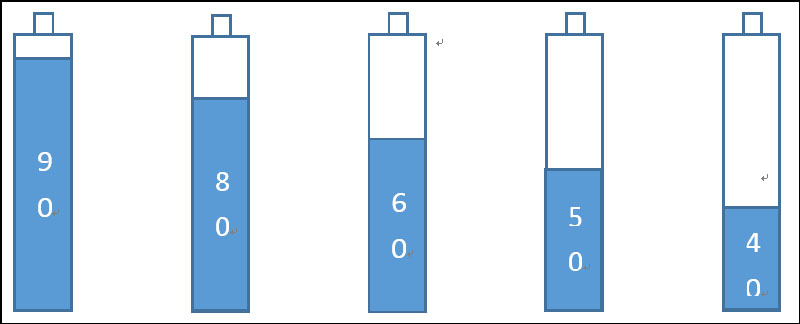

Once the power battery has been in use for a while, the individual cell's state of charge (SOC) aligns with the illustration provided. The maximum SOC is 90%, while the minimum SOC is 40%. The power battery's overall SOC is determined by the lowest SOC within the battery pack, which in this case is 40%.

When the single cell with low SOC is fully charged, the power battery cannot be discharged at this time. If it is discharged again, it will cause damage to the cell with the smallest SOC. In this case, the battery pack actually still has a lot of remaining power. This is what we call the barrel principle.

The same goes for charging. When the battery cell with high SOC is fully charged, the battery cell with low SOC is not yet fully charged. At this point, it is no longer possible to charge the battery pack. If it is recharged, it will cause great damage to the fully charged cells (commonly known as overcharging, with the risk of explosion and fire).

The purpose of balancing power batteries using the EB480 battery pack cell balancer is to solve the above wooden barrel effect. It can balance the entire power battery in an integrated manner. The balancing speed is faster than single cell balancing and module balancing, and it also makes balancing The effect is more accurate.

1. Connect the cable to the battery pack

First, insert the quick connection strip connector of the lithium battery balancing wire into the corresponding terminal of the tester. Then connect the other end of the discharge wire to the battery box end (connect the red connector of the balancing wire to the positive terminal of the battery module that needs to be balanced in order, and connect the black connector to the total negative terminal of the battery module that needs to be balanced).

2. AC power input

Connect the AC input power cord equipped with the instrument to the corresponding interface, and pay attention to the load output of the power socket (single-phase three-wire 220V input, maximum input 10A).

3. Balance settings

Select [Balanced Maintenance] from the main menu, click the Settings button to enter the battery pack setting interface of balanced maintenance (if the battery pack wiring fails or is not connected, "Not Connected" or "Connection Fault" will be displayed).

4. Start testing

In the "Balanced Maintenance" interface, click the [Start] button to start the test. After the test is successfully started, you can view the cell voltage, working current, working status, test duration, capacity and other parameters of the corresponding test group.

5. Equilibrium completion conditions

When the maintenance cell voltage reaches the target value, the status of the single cell is displayed as [Complete], and when all working cell channels are [Completed], the entire working unit channel is balanced and the work is completed.

Return