Autumn has arrived, and the heat is still lingering in many southern cities. Many electric vehicle repair shops have discovered that during the season of high temperatures, electric vehicles are prone to refrigeration system failures:

After checking the cause, the problem basically lies in the compressor.

The compressor is a core component in the cooling system and makes a huge contribution to the cooling system of electric vehicles.

In general, it will work for two systems: one is to cool the interior space of the car, and the other is to help cool the battery.

Similar to household air conditioners, automotive air conditioners also use the state cycle of refrigerant compression, condensation, expansion and evaporation to achieve temperature control. The main components include compressor, condenser, expansion valve, dryer and evaporator.

From the most straightforward physical principle, the evaporator changes the refrigerant from liquid to gas, which is a process of absorbing heat and lowering the surrounding air's temperature. At this time, the fan can blow the cold air into the passenger compartment, bringing us a relaxed driving and riding experience.

When the refrigeration system works, it will go through four stages:

① Compression process

The compressor starts to work, sucking in low-temperature and low-pressure gaseous refrigerant from the low-pressure pipeline, and compressing it into high-temperature and high-pressure gaseous refrigerant;

② Condensation process

The high-temperature and high-pressure gaseous refrigerant enters the condenser through the high-pressure pipeline. After being cooled by the condenser, it turns into high-temperature and high-pressure liquid refrigerant;

③ Cool down and reduce blood pressure

The liquid refrigerant is sent to the liquid storage dryer. After drying and filtration, it flows into the expansion tube through the high-pressure pipeline, is throttled through the small hole of the expansion tube, and becomes a low-temperature, low-pressure mist-like liquid/gas mixture;

④ Evaporation endothermic process

The mixture is fed into the evaporator, where the refrigerant expands, evaporates and absorbs a large amount of heat. During this process, the blower continuously blows the cold air on the surface of the evaporator into the car to achieve cooling.

Finally, the refrigerant that has absorbed a large amount of heat is re-vaporized into a low-temperature and low-pressure gaseous refrigerant, which is sucked into the compressor for recirculation.

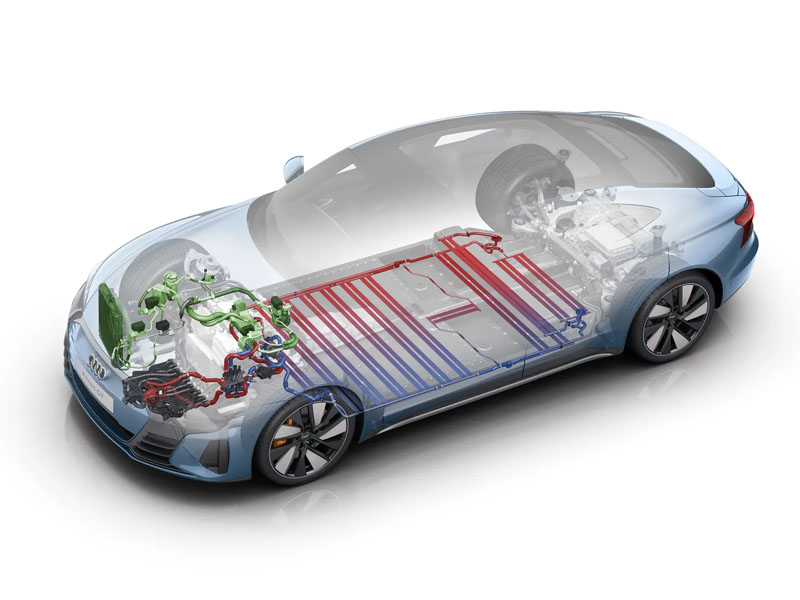

In addition to controlling the temperature inside the car, the air conditioning system also needs to take care of the temperature of the power battery. The battery will have an "electrothermal effect" during the charging and discharging process. How to keep the battery at the optimal operating temperature will have a great impact on the battery life and endurance performance of electric vehicles. Electric vehicles generally use air conditioning circulation cooling and liquid cooling systems.

① Air conditioning circulation cooling

The former has a pipeline connected to the air-conditioning coolant inside the battery, which is connected in parallel with the original air-conditioning circulation pipeline. One is used to cool the battery, and the other is used to cool the interior space of the car. This technology is commonly used in plug-in hybrid vehicles.

② Liquid cooling system

The liquid cooling system installs a separate coolant kettle for the electric vehicle and uses the cooling water pump and battery cooler to achieve heat exchange and maintain the operating temperature of the battery pack.

Unlike fuel vehicles, electric vehicles do not have an engine and cannot extract the power of the engine to the compressor through a belt. Therefore, whether it is air conditioning cycle cooling or battery liquid cooling cycle, part of the power of the compressor will be occupied.

In summer, when the temperature is too high and air conditioning and liquid cooling are used at the same time for a long time, the compressor will directly "strike" due to being overwhelmed.

Return