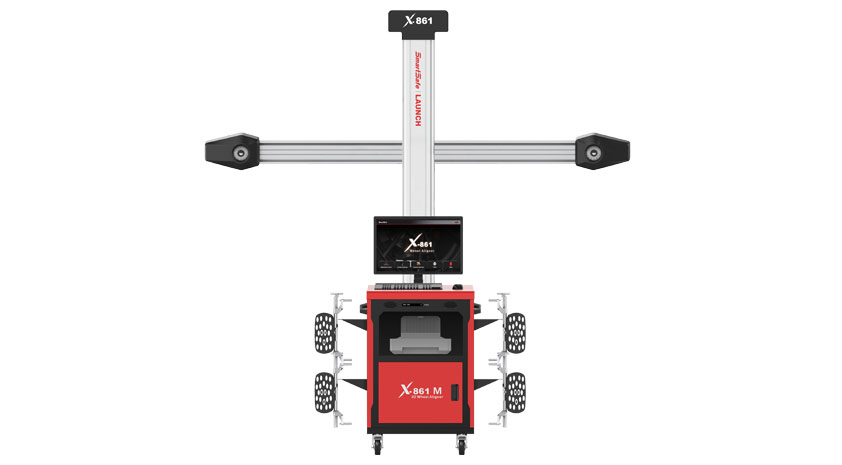

X-861 series 3D wheel alignment machine mainly consists of column assembly, lateral beam assembly (includes camera), cabinet, computer host, monitor, printer, targets, clamps, communication cables, turntables(standard), steering wheel holder, brake pedal depressor, etc.

X-861 series 3D wheel alignment machine has 4 targets (come together with 4 clamps). It is a key component for acquiring raw data of wheel alignment. Cameras will capture target images for data processing. On the back of the target, there’s identification label for target position.

X-861 series 3D wheel aligner has two cables between computer and lateral beam, one is USB data cable, and another one is power supply cable. Please keep them in good condition to avoid damage to the entire alignment system.

X-861 series 3D wheel aligner comes with 2 mechanical turntables. The turntable shall be placed on the front wheel position on the lift. Each turntable has a pair of transit bridges and a pair of brake blocks, placed between the turntable and the lift, to ensure the vehicle moves smoothly when doing rolling compensation.

X-861 Series 3D wheel aligner is equipped with a steering wheel holder. In order to ensure that the direction of the vehicle does not change during the test, it is necessary to place the steering wheel bracket as prompted.

X-861 Series 3D wheel aligner is equipped with a brake pedal depressor. It is used to press down the brake pedal, to prevent vehicles from moving at certain measurement stages, e.g., caster swing.

|

Model |

|||||||

|

Precision

|

Measure Range

|

Precision

|

Measure Range

|

Precision

|

Measure range

|

||

|

Technical parameter

|

Display accuracy

|

1'/0.01/0.1mm |

/

|

1'/0.01/0.1mm

|

/

|

1'/0.01/0.1mm

|

/

|

|

Toe angle

|

±2'

|

±40°

|

±2'

|

±20°

|

±2'

|

±20°

|

|

|

Camber angle

|

±2'

|

±10°

|

±2'

|

±20°

|

±2'

|

±20°

|

|

|

Caster angle

|

±4'

|

±20°

|

±4'

|

±20°

|

±4'

|

±20°

|

|

|

Kingpin inclination angle

|

±6'

|

±20°

|

±6'

|

±20°

|

±6'

|

±20°

|

|

|

Thrust line angle

|

±2'

|

±10°

|

±2'

|

±10°

|

±2'

|

±10°

|

|

|

Wheel Track

|

±2mm

|

2500mm

|

±2mm

|

2500mm

|

±2mm

|

2500mm

|

|

|

Wheelbase

|

±2mm

|

4000mm

|

±2mm

|

4000mm

|

±2mm

|

4000mm

|

|

|

Other info

|

Upper screen

|

24 inch wheel alignment

|

32 inch wheel alignment

|

24 inch wheel alignment

|

|||

|

Secondary screen

|

Optional with 19 inches one

|

Optional with 19 inches one

|

Optional with 19 inches one

|

||||

|

Camera definition

|

5MP

|

1.3MP

|

1.3MP

|

||||

|

Printer

|

1 pc

|

Optinal

|

Optinal

|

||||

|

Overall Movable

|

YES

|

N/A

|

YES

|

||||

|

Auto Trace Function

|

YES

|

N/A

|

N/A

|

||||

Ask the owner for vehicle drivability problems, symptoms, and wheel alignment history, and find out vehicle information such as country of origin, make, model and year, etc. Then check whether the tire pressure, tire size and treads of the left and right wheels are alike. Communicate with the owner in case of any abnormal conditions found. Run the test together with the owner if necessary, to confirm the problem and take measures to ensure the accuracy of the measurement.

Perform test drive after alignment adjustment is complete, to confirm if the fault phenomena are eliminated. Otherwise, redo the adjustment.

SmartSafe Wheel Aligner is a high-tech device that allows you to perform precise wheel alignment on vehicles quickly and easily. It uses advanced technology and algorithms to provide accurate and reliable measurements, making it an ideal choice for automotive professionals.

1. High-resolution cameras that capture precise measurements.

2. Automatically adjusts the height of the camera beam according to the height of the target

3. User-friendly interface and software that makes it easy to operate.

4. Portable design that allows you to move it from one location to another with ease.

5. Cost-effective solution that can help save time and money by reducing the need for rework and corrections.

Overall, if you are looking for a reliable and efficient solution for wheel alignment, SmartSafe Wheel Aligner could be an excellent choice for you.

Return